Introduction to organic fertilizer dryer:

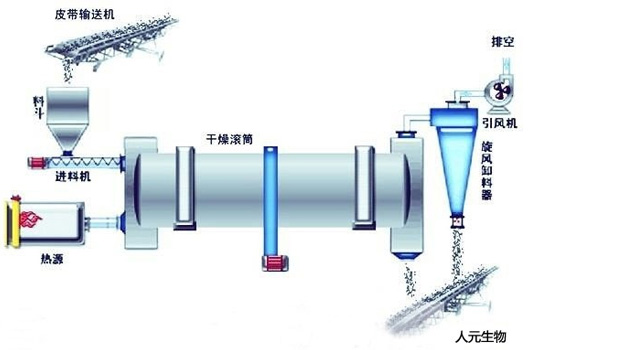

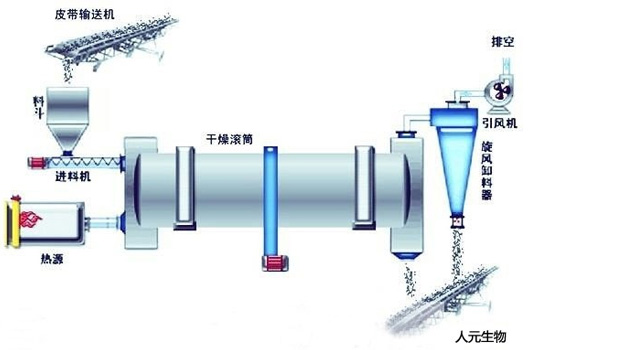

Organic fertilizer dryer is a kind of widely used organic fertilizer drying equipment, which has the advantages of reasonable structure, high output, low energy consumption, convenient operation etc. The equipment is mainly composed of heat source, feeding machine, rotary drum, discharging machine, material crushing device, induced draft fan, unloader and power distribution cabinet.

Characteristics of organic fertilizer dryer:

Characteristics of organic fertilizer dryer:

The organic fertilizer dryer can directly dry the feces with a moisture content of 70% - 80% to 13% safe storage moisture at one time. The whole process is carried out in a closed system, thus reducing the environmental pollution during the drying process. After the dehydrated semi wet materials are added to the dryer, the organic fertilizer materials are evenly dispersed in the dryer and fully contacted with the hot air under the turning of the plate reader evenly distributed in the drum, which accelerates the drying heat and mass transfer. During the drying process, the materials will be discharged to the outlet at the other end of the dryer under the action of the inclined plate and the hot gas.

Precautions for use of organic fertilizer dryer:

1. The installed dryer shall be subject to no-load test run for no less than 4 hours. Any abnormal situation during the test run shall be handled in time. After the test run, tighten all the connecting bolts again, check and replenish the lubricating oil, and carry out the load test run after the test run is normal; Before the load test run, each auxiliary equipment shall be subject to the single empty test run; After the single unit test run is successful, it will be transferred to the joint test run.

2. Ignite the hot-air stove to preheat the organic fertilizer dryer, and turn the dryer on at the same time. It is prohibited to heat the barrel without rotating to prevent the barrel from bending. According to the preheating condition, gradually add wet materials into the drying drum, and gradually increase the feeding according to the moisture content of the discharged materials. The preheating of the organic fertilizer dryer needs a process, and the hot-air stove should also have a preheating process. It is prohibited to burn suddenly. Prevent equipment damage caused by local overheating and uneven thermal expansion.

It is inevitable that the organic fertilizer dryer breaks down in the working process. The following contents are the problems and solutions in the use process.

Problems and solutions in the use of organic fertilizer dryer:

1. The reason why the base of rotary drum organic fertilizer dryer resonates is that during the production of the dryer, due to the strong rotation of the equipment, it will produce some resonance effects with the base, which is very harmful to the equipment, and will cause excessive shaking of the materials in the barrel, resulting in the phenomenon of drying.

Solution: when building the base of the organic fertilizer dryer, it is poured with cement and added with a shockproof wood bed. Secondly, during production, pay attention to the actual capacity of the machine, and do not exceed it to overload the machine. The inside of the machine should be cleaned frequently to prevent the accumulation of surplus materials.

2. Blocking at the outlet of the organic fertilizer dryer: the reason is that the material containing more water is easy to form a block, and the blocking phenomenon will occur when reaching the outlet of the organic fertilizer dryer, which makes the material outlet unblocked.

Solution: in addition to strictly controlling the process formula, if the particle size of the material entering the organic fertilizer dryer is found to be large, the relevant personnel shall be informed in time to pay attention to the discharge at the tail of the machine, so as to prevent the bag film, bag line and other sundries in the production raw materials from entering the production system.

3. The meshing clearance between the large gear and the small gear is damaged: the reason is that the tug is worn, the stopper is worn, and the small gear is worn.

Solution: cancel or replace it according to the wear condition, or install it on the opposite side or update it in pairs.

4. Unstable working current of the motor: the reason is that the load is increased due to the binding material between the barrel wall of the organic fertilizer dryer and the sheet. According to the normal production process formula, spray granulation is to dissolve ammonium nitrate or urea with water and steam as the liquid phase. There is much water in the liquid phase, so the granulation material has high water content and high viscosity, which is easy to bond on the barrel wall of the organic fertilizer dryer and the internal plate, and increases the working load of the equipment.

Solution: starting from the process formula, the liquid phase concentration should be increased as much as possible to reduce the water content. The raw materials with high water content should be treated before use.